The diesel generator set (DG set) is a cornerstone of modern power supply systems, serving as a reliable energy source in industrial plants, commercial complexes, healthcare facilities, infrastructure projects, and emergency backup systems. In critical applications, the ability of a DG set to start and deliver power promptly can be the difference between operational continuity and costly downtime.

At the heart of DG set reliability lies the starting system, a subsystem responsible for initiating engine rotation, enabling fuel combustion, and bringing the engine up to self-sustaining speed. The starting system must be robust, responsive, and fail-safe, as even momentary starting failures can compromise operations, especially in emergency scenarios such as hospital backups, data center power supply, or oil and gas facilities.

This article provides a comprehensive overview of diesel generator starting systems, covering their key components, operating principles, control logic, auxiliary aids, common faults, maintenance practices, and safety considerations.

The primary function of a DG set starting system is to rotate the engine crankshaft to a sufficient speed to allow air compression and fuel injection to generate combustion. Once combustion becomes self-sustaining, the starter disengages, and the engine continues running independently.

Key roles of the starting system include:

- Rapid power availability: Ensures minimal delay in power delivery during outages or emergencies.

- Support for automation: Enables remote or automatic start in standby applications.

- Engine protection: Proper starting reduces mechanical stress and prolongs engine life.

- Reliability in critical facilities: Vital for hospitals, data centers, oil & gas installations, and industrial plants where downtime is costly.

Diesel engines differ from gasoline engines in requiring high starting torque due to compression ignition. This necessitates a starting system that is more robust and complex, capable of overcoming high resistance in cold environments or under heavy load.

While designs vary according to generator size, power rating, and application, most diesel generator starting systems comprise four fundamental components:

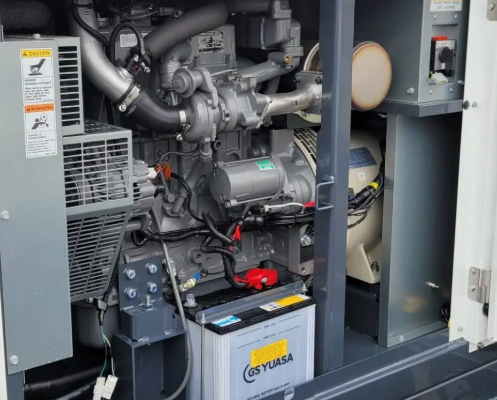

The starting power source supplies the energy required to rotate the engine:

- Storage batteries: Most common in small- to medium-sized generators. High-current lead-acid or lithium-ion batteries are used to provide the necessary cranking power.

- Compressed air: Used in large industrial engines or marine applications. Air is stored in tanks at high pressure for immediate release.

- Hydraulic accumulators: Less common, typically used in specialized applications such as military or offshore systems where battery or air systems are impractical.

The starter converts stored energy into mechanical torque:

- Electric starter motor: Standard for most commercial DG sets.

- Air starter motor: Typically vane-type or piston-type motors for large engines.

- Hydraulic starter motor: Drives the flywheel using stored hydraulic pressure, suitable for compact, high-power applications.

This mechanism temporarily connects the starter to the engine flywheel and disengages after the engine starts:

- Bendix drive: Uses helical gear teeth to engage/disengage the starter automatically.

- Solenoid-actuated pinion gear: Engages the flywheel through electrical or hydraulic actuation.

The control system governs safe and reliable operation:

- Manages start sequence timing.

- Prevents starter engagement under unsafe conditions (low battery voltage, high engine temperature, etc.).

- Provides overload protection and fault alarms.

Electric starting systems are prevalent in small to medium-sized DG sets due to their simplicity, maturity, and ease of integration with automatic controllers. They rely on batteries to power high-torque electric starter motors.

- Starting battery: 12V, 24V, or higher depending on engine size. Large engines may require 48V or 96V systems.

- Starter motor: High-torque DC or permanent magnet motors.

- Starter solenoid: Engages pinion gear and closes the high-current circuit.

- Battery charger: Maintains optimal charge.

- Control relay and wiring: Interfaces with engine controller and monitoring system.

- Start command issued manually or via automatic controller.

- Starter solenoid engages the pinion gear with the flywheel and connects the starter to the battery.

- Starter motor rotates the engine crankshaft and pistons.

- Fuel injection occurs as the engine reaches minimum cranking speed, causing compression ignition.

- Starter disengages automatically once the engine achieves self-sustaining speed.

- Mature technology with wide availability.

- Compact design suitable for most applications.

- Easy maintenance with straightforward troubleshooting.

- Compatible with automatic start systems.

- Battery performance deteriorates over time and in cold climates.

- Limited cranking duration for high-compression engines.

- Requires periodic load testing and maintenance.

Air starting systems are used for large DG sets and heavy-duty industrial engines. Instead of electricity, compressed air provides the energy for initial engine rotation.

- Air compressor: Supplies high-pressure air.

- Air storage tanks: Store pressurized air for immediate use.

- Air starter motor: Converts compressed air into rotational torque.

- Distribution manifold and control valves: Direct air flow into the motor or cylinders.

- Air is released from storage tanks through control valves.

- Compressed air drives the air starter motor or enters engine cylinders directly, rotating the crankshaft.

- Once the engine reaches operating speed, valves close automatically.

- Provides high starting torque for large engines.

- Reliable in extreme cold or adverse conditions.

- Does not depend on battery health.

- Requires complex piping and maintenance of air compressors.

- Larger installation footprint.

- Continuous maintenance of air system is critical.

Hydraulic starters are used in specialized environments where batteries or air systems are impractical. They store energy in pressurized fluid for rapid engine startup.

- Hydraulic fluid from an accumulator drives a hydraulic motor attached to the flywheel.

- Upon receiving a start command, control valves release fluid to the motor, rotating the engine.

- After startup, fluid is returned to the accumulator for recharge.

- Compact energy storage and high reliability.

- Can operate in confined or remote locations.

- Expensive and requires specialized hydraulic maintenance.

- Less common in commercial applications.

Modern DG sets employ sophisticated controllers to automate and protect the starting process:

- Pre-start checks: Oil pressure, coolant temperature, fuel availability.

- Cranking limits: Prevents motor burnout.

- Retry logic: Automatic retries after failed attempts.

- Fault alarms and shutdowns: Immediate notification for electrical or mechanical faults.

In emergency standby systems, controllers receive signals from an Automatic Transfer Switch (ATS) upon utility power loss and execute the start sequence automatically, often in under 10 seconds.

Low ambient temperatures increase oil viscosity and reduce fuel atomization, complicating engine startup. Cold-start aids include:

- Engine block heaters: Electrically warm engine coolant and oil.

- Intake air heaters: Preheat incoming air for better combustion.

- Glow plugs: Electrically heat combustion chambers in smaller engines.

- Fuel heaters: Warm diesel fuel to improve atomization.

These measures enhance reliability and reduce mechanical stress during startup in cold climates.

Even robust systems can fail. Common issues include:

- Battery-Related Faults: Low charge or voltage, Sulfation on plates, Loose or corroded terminals

- Starter Motor Problems: Worn brushes or bearings, Solenoid failure, Mechanical jamming

- Control Circuit Failures: Defective relays or sensors, Improper controller programming, Wiring faults

- Mechanical Resistance: High-viscosity oil or fuel, Engine seizure and Flywheel damage

Preventive maintenance and early detection are key to avoiding unexpected downtime.

Routine maintenance is essential for DG set reliability:

- Test battery voltage and electrolyte levels.

- Inspect starter motor, brushes, and solenoid.

- Verify control circuit functionality and alarms.

- Perform periodic load testing of batteries.

- Inspect cables, terminals, and grounding connections.

- Conduct regular test starts for standby generators to ensure readiness.

Starting systems involve high currents, pressurized fluids, or compressed air:

- Always observe proper grounding and insulation protocols.

- Use pressure relief devices and check valves where applicable.

- Implement lockout/tagout procedures during maintenance.

- Ensure personnel are trained in safe handling of batteries, high-current circuits, and hydraulic systems.

The starting system is a critical determinant of diesel generator performance, reliability, and operational safety. From electric and air starters to hydraulic systems, control logic, and cold-start aids, each component plays an essential role in ensuring the generator starts successfully under any condition. Effective maintenance, proper component selection, integration with modern controllers, and attention to environmental conditions are indispensable to minimizing downtime and maximizing generator availability. For critical applications, understanding and optimizing the starting system is as important as selecting the engine itself.