What are Base-Mounted Fuel Tanks for Diesel Generator?

On this page

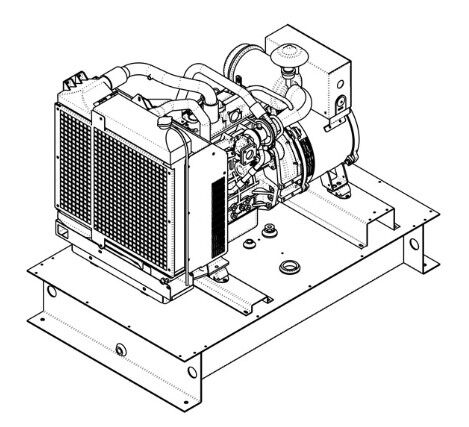

Diesel generator fuel tank systems are primarily categorized into two types: base-mounted fuel tanks and standalone storage tanks. Base-mounted fuel tanks are typically installed beneath the generator set, forming an integrated unit with a compact structure and an aesthetically pleasing appearance. They are mainly used in generator sets below 550 kW, such as silent-type generators. These fuel tank systems play a critical role in ensuring continuous operation and stable fuel supply for the diesel generator set. Their design, functionality, and maintenance significantly impact the equipment's performance and longevity.

Base-mounted fuel tanks are usually rectangular in design, often featuring a double-wall structure to enhance leak resistance and prevent fuel spillage effectively. These tanks typically include the following components.

Vent and Pressure Relief Valve: Maintains internal pressure balance within the tank to prevent overpressure hazards.

Return Fuel Device and Fuel Alarm: Monitors fuel return and liquid level. When the fuel level approaches 95% of the tank’s capacity, the intake valve of the return fuel device automatically closes to prevent overflow and wastage.

Anti-Spill Protection: The double-wall design ensures that even if the inner wall is damaged, the outer wall can still prevent fuel leakage, reducing environmental pollution risks.

The traditional design of base-mounted fuel tanks comprises the tank itself, longitudinal beams, and sealing plates. The ventilation openings between the sealing plate and the base-mounted tank help dissipate heat from the generator set, expelling heat and exhaust gases through top or side exhaust systems. However, this design poses safety risks in specific environments, such as high-altitude areas, wilderness, or heavy rain. Small animals and insects can easily enter the unit through the ventilation openings, gnawing on wires and causing generator failure or shutdown. Additionally, heavy rain might infiltrate through intake and exhaust vents, leading to electrical system short circuits and increasing the risk of fire.

Different fuel tank types have distinct structural and functional characteristics. Single-wall tanks are preferred for many standard diesel generator sets due to their simple structure and cost-effectiveness, while double-wall tanks are widely used in special applications due to their excellent protective features. Below is a detailed comparison of the advantages and applications of these two tank types.

Single-wall fuel tanks have a straightforward structure, with a single layer of metal separating the tank’s interior from the external environment. They are commonly used in indoor generator sets because of their low manufacturing costs and simple design. However, due to the lack of an additional protective layer, single-wall tanks are prone to fuel leakage in harsh external environments or in the presence of impact risks, potentially leading to environmental pollution.

Double-wall fuel tanks add an extra protective structure based on the single-wall design, featuring inner and outer walls. The inner wall prevents fuel leakage, while the outer wall provides additional protection, ensuring that fuel leakage is contained even if the inner wall is damaged. This design is more suitable for environments with high environmental protection requirements. Although double-wall tanks have higher manufacturing costs, they offer significant advantages in preventing environmental pollution and enhancing equipment safety.

As a part of diesel generator sets, base-mounted fuel tanks are closely integrated with the unit, offering various structural and functional benefits but also presenting some limitations. Below is an analysis of the main advantages and disadvantages of base-mounted fuel tanks.

Space-Saving: The base-mounted fuel tank is integrated with the generator set, featuring a compact structure that effectively reduces the footprint, leaving more room for other equipment.

Enhanced Stability: The design of the base-mounted fuel tank increases the contact area between the generator set and the ground, improving the load-bearing capacity and enhancing the stability of the equipment during operation.

Aesthetic and Cohesive Appearance: The close integration of the tank and the unit results in a cohesive appearance, enhancing the overall aesthetic of the generator set.

Difficult Maintenance: Due to the low position and complex structure of the base-mounted fuel tank, cleaning and sludge discharge are challenging, especially when sediment forms inside the tank due to organic impurities and water in diesel.

Leakage Risk: Base-mounted tanks made from synthetic materials are susceptible to chemical reactions with diesel containing impurities over long periods, leading to material degradation and increased leakage risk.

High Manufacturing Costs: Compared to standalone tanks, base-mounted tanks have a more complex design and manufacturing process, resulting in higher costs.

To ensure safe and efficient operation of diesel generator sets with base-mounted fuel tanks, users should take the following measures.

Regular Cleaning: Given the difficulty in cleaning base-mounted tanks, it is essential to periodically inspect the tank interior and promptly clean any sediment to prevent contamination from impurities and moisture.

Install Drainage Pipelines: Installing drainage pipelines at the bottom of the tank facilitates the regular discharge of sediment and moisture, helping maintain a clean interior.

Install Protective Devices: Protective meshes or grilles should be installed at ventilation and exhaust openings to prevent small animals and insects from entering the unit and damaging cables and control systems.

In conclusion, the design and selection of diesel generator fuel tank systems must comprehensively consider the generator's power capacity, operating environment, and maintenance convenience. Base-mounted tanks, with their compact structure, cohesive integration, and minimal footprint, are ideal for small to medium power generators, especially in applications with limited space or frequent mobility requirements. However, due to the challenges of maintenance and higher manufacturing costs, users should weigh the pros and cons based on their specific needs before making a choice.