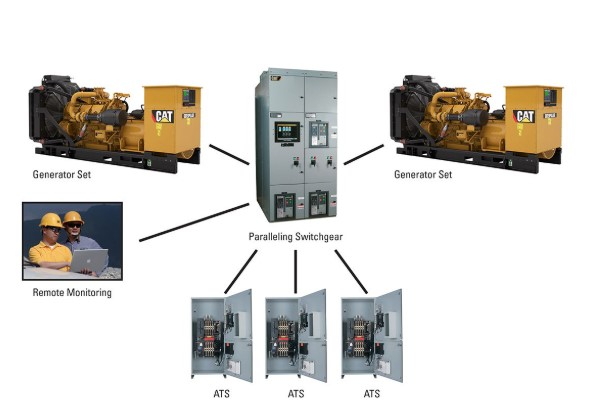

In power systems, the parallel operation of generator sets is a critically important operation. It not only ensures the stability and reliability of power supply, but also improves power generation efficiency and enhances system flexibility. This article will introduce in detail the principles, operating procedures, precautions, and maintenance key points of generator set parallel operation, helping readers gain a comprehensive understanding of this complex and critical process.

Generator set parallel operation refers to connecting a generator set that is already in operation with another generator set that is ready to be paralleled, allowing them to operate together. This process is known as synchronization. The core objective of synchronization is to avoid harmful inrush current at the moment of breaker closing, ensure that the shaft is not subjected to sudden impact, and allow the rotor to be quickly pulled into a synchronous state after closing (that is, the rotor speed equals the rated speed).

The importance of parallel operation is beyond doubt. It not only improves the power supply capacity and reliability of the power system, but also optimizes resource allocation and improves power generation efficiency. In addition, parallel operation enhances system flexibility, making it easier to adjust under different load conditions.

To achieve safe and stable parallel operation, generator sets must meet the following conditions:

- Equal Voltage: The voltages of the two generator sets must be the same. This can be monitored and adjusted using a voltmeter.

- Equal Frequency: The frequencies of the two generator sets must be the same. A frequency meter can be used to monitor frequency differences.

- Phase Consistency: The phase of the two generator sets must be consistent. This can be monitored using a synchroscope and non-synchronizing indicator lamps.

These conditions are achieved through the quasi-synchronous method. The quasi-synchronous method is a precise method for controlling parallel operation. By accurately adjusting voltage, frequency, and phase, it ensures the smooth completion of the synchronization process.

Quasi-synchronous parallel operation is an operation that requires a high degree of precision and experience. The detailed steps are as follows:

- Start the First Generator Set

- Close the load switch of one generator set to supply voltage to the busbar.

- Preparation of the Incoming Generator Set

The other generator set remains in the incoming (to-be-paralleled) state, ready for synchronization.

- Close the Synchronizing Switch: Close the synchronizing switch and begin monitoring the voltage, frequency, and phase of both generator sets.

- Adjust Speed: Adjust the speed of the incoming generator set so that it is equal to or close to synchronous speed (the frequency difference from the other generator set is within half a cycle).

- Adjust Voltage: Adjust the voltage of the incoming generator set so that it is close to the voltage of the other generator set.

- Observe the Synchroscope: When the frequency and voltage are close, the rotation speed of the synchroscope pointer becomes slower, and the synchronizing lamps alternately brighten and dim.

- When the phase of the incoming generator set is the same as that of the other generator set, the synchroscope pointer points to the upper center position, and the synchronizing lamp is the darkest.

- When the phase difference is at its maximum, the synchroscope pointer points to the lower center position, and the synchronizing lamp is the brightest.

- Frequency Adjustment: Adjust the speed of the incoming generator set according to the rotation direction of the synchroscope pointer. If the pointer rotates clockwise, it indicates that the frequency of the incoming generator is higher than that of the other generator set, and the speed of the incoming generator set should be reduced. Conversely, the speed of the incoming generator set should be increased.

- Closing Timing: When the synchroscope pointer rotates slowly in the clockwise direction and approaches the synchronizing point, immediately close the circuit breaker of the incoming generator set to parallel the two generator sets.

- Removal of Synchronizing Equipment: After parallel operation, remove the synchroscope switch and related synchronizing switches.

- Conditions Under Which Closing Is Prohibited: When the synchroscope pointer jumps, closing is prohibited, because there may be sticking inside the synchroscope, making it unable to reflect correct synchronization conditions. When the synchroscope rotates too fast, it indicates that the frequency difference between the incoming generator set and the other generator set is too large, and closing is prohibited. If the synchroscope pointer stays at the synchronizing point without moving, closing is prohibited, because if the frequency of one generator set suddenly changes during breaker closing, the breaker may close at a non-synchronous point.

- Operating Experience: Quasi-synchronous parallel operation is a manual operation, and its success is closely related to the operator’s experience. Therefore, operators must receive professional training and possess extensive practical experience.

After synchronization is completed, a series of adjustments and monitoring tasks are required to ensure stable operation of the two generator sets.

- Frequency Difference Adjustment: If the frequencies of the two generator sets are not equal and the difference is large, instruments (ammeters and power meters) will indicate reverse power. At this time, adjust the speed (frequency) of one generator set according to the power meter indication until the power meter reading returns to zero.

- Voltage Difference Adjustment: When both power meters indicate zero while the ammeters still show current (one negative and one positive), this reverse power phenomenon is caused by voltage difference. At this time, adjust the voltage adjustment knob of one generator set according to the ammeter and power factor indications until the ammeter reading is eliminated (adjusted to zero). Then, according to the power factor meter indication, adjust the power factor to lagging above 0.5, with approximately 0.8 being the optimal condition.

- Protection Settings: The overload capacity of generator sets is very low, generally about 5% of rated power, with an allowable load duration of 15–30 minutes, and a maximum of no more than 60 minutes. Exceeding this time will cause the generator set to heat up and reduce conductor insulation, thereby shortening service life. Therefore, unless there are special requirements, the overcurrent protection setting should be 110% of rated current.

- Load Test: During load testing, increase the current to 110% of rated current. The overcurrent relay should operate, causing tripping and alarm, but without stopping the generator.

- Protection Settings: Generator sets operating in parallel are all equipped with overvoltage protection. The optimal setting value is 105% of rated voltage. Short-circuiting the overvoltage relay will cause tripping, shutdown, and alarm operation.

- Oscillation Monitoring: During parallel operation of generator sets, system oscillation is the most dangerous condition. Once oscillation occurs, system voltage rises easily, causing insulation breakdown of electrical equipment and power supply equipment, leading to simultaneous failure of both supply and load equipment. Therefore, system voltage must be closely monitored to prevent oscillation.

With technological development, automatic synchronization control modules have been widely applied in generator set parallel operation. These modules can automatically detect voltage and speed of the generator sets and issue breaker closing commands after identifying the synchronizing point, allowing the generator sets to operate in parallel.

- Signal Detection: After the first generator breaker is closed, the bus synchronization circuit and the incoming generator synchronization circuit receive signals, and the synchronization detection relay closes automatically.

- Voltage and Speed Detection: Bus voltage and incoming generator voltage are sent to the synchronization control module, which automatically detects voltage and speed of the generator sets.

- Automatic Adjustment: If there is a speed difference, the synchronization module automatically adjusts the speed of the incoming generator set to meet synchronization conditions.

- Closing Command: After the synchronizing point is identified, the synchronization module issues a closing command. Upon receiving the command, the incoming generator set closes its breaker, and the generator sets operate in parallel.

- Exit from Operating State: After generator sets are paralleled, the synchronization circuit exits operation automatically. However, the automatic synchronization selector switch must be manually disengaged to prevent the incoming generator set from receiving a synchronization signal again during separation and re-energization, which would cause the synchronization device to automatically engage and re-parallel the generator sets.

- Single-Unit Operation: During single-generator operation, the load sharing controller is not activated.

- Function of Load Sharing Controllers: After generator sets are paralleled, each load sharing controller is activated simultaneously and adjusts its own speed so that power is evenly distributed between the generator sets. The operating principle is based on the output power of each generator set (that is, current magnitude), automatically adjusting speed to achieve load balance.

- Power Factor Adjustment: Before synchronization, the voltages of both generator sets must be adjusted to the same value. After no-load parallel operation, adjust the voltage knob to eliminate reverse power and maintain a lagging power factor of approximately 0.8. After the paralleled generator sets are loaded, manually adjust the voltage knob according to load conditions to maintain the power factor at the optimal position. Further adjustment is generally unnecessary afterward.

Before performing parallel operation, a series of inspections and maintenance tasks must be carried out to ensure smooth operation and safe equipment performance.

Instrument Adjustment: Before operation, all relevant instruments must be adjusted to zero, except for the power factor meter and frequency meter.

Instrument Operating Condition: During operation, observe whether instrument operation meets requirements (such as incorrect wiring). Current and voltage should be verified using appropriate instruments to confirm that indicated values are normal.

Starting Circuit Inspection: Before operation, the starting circuit must be checked first. After starting, verify that related components operate normally, that engagement between the starter and the prime mover is normal, and that disengagement is possible.

Shutdown Inspection: Check whether the shutdown solenoid and solenoid valve operate reliably, whether the generator automatically shuts down during faults, whether the manual shutdown circuit is complete, and whether situations such as shutdown during breaker tripping occur.

Parallel operation of generator sets is a complex and critical operation that requires precise control and extensive experience. Using the quasi-synchronous method for parallel operation effectively avoids harmful inrush current and shaft impact, ensuring stable generator operation. Post-parallel adjustments and monitoring are equally important. Through proper load sharing and power factor adjustment, generator operating efficiency can be optimized. In addition, pre-operation inspection and maintenance are essential safeguards for safe equipment operation.

It is hoped that this article helps readers gain a comprehensive understanding of the principles, operating procedures, precautions, and maintenance points of generator set parallel operation. In actual operation, procedures must be strictly followed to ensure safe and stable operation of generator sets.