In modern industrial and commercial environments, diesel generator sets are widely used as standby or primary power sources. However, when purchasing and operating diesel generator sets, many users tend to overlook a critical component, the power cable. Power cables are not only the physical link between the generator and the load, but also a vital guarantee for safe power transmission and stable equipment operation. This article provides an in-depth discussion of the classification of power cables for diesel generator sets, cable selection methods, and key considerations in practical applications, helping users better understand and choose appropriate cables.

Power cables for diesel generator sets are mainly classified according to the type of sheath used. The sheath is a crucial component of a cable: it protects the insulation from environmental influences and determines the cable’s application range and performance characteristics. Based on sheath materials and structures, power cables can be divided into the following categories.

Metallic sheaths are completely watertight and effectively prevent moisture and other harmful substances from entering the cable insulation. They are widely used in oil-impregnated paper-insulated power cables with low moisture resistance and in extra-high-voltage cables. Common materials for metallic sheaths include aluminum, lead, and steel. According to manufacturing methods, metallic sheaths can be divided into hot-extruded metal sheaths and welded metal sheaths. In addition, some cables use formed metal pipes as sheaths, such as steel-pipe cables.

Metallic sheaths offer excellent waterproof performance and high mechanical strength, but they are relatively heavy and more complex to install and maintain.

Rubber and plastic sheaths are widely used in mobile cables due to their flexibility and light weight. These materials have a certain degree of water permeability and are therefore suitable only for cables that use highly moisture-resistant polymer insulation materials.

The structure of rubber and plastic sheaths is relatively simple, typically consisting of a single outer sheath. Generally, rubber-insulated cables use rubber sheaths, though plastic sheaths may also be used; plastic-insulated cables always use plastic sheaths. The main advantages of rubber and plastic sheaths are good flexibility and ease of installation and movement, but their waterproof performance is comparatively limited.

Composite sheaths, also known as integrated or simplified metallic sheaths, are widely used in plastic communication cables and have also gained increasing attention in plastic power cables. A typical composite sheath consists of a thin aluminum tape bonded to a polyethylene outer sheath.

This structure retains the flexibility and light weight of plastic cables while significantly reducing water permeability due to the moisture barrier provided by the aluminum tape. The water permeability of an aluminum–polyethylene bonded composite sheath can be more than 150 times lower than that of a polyethylene sheath alone. By combining the advantages of metallic and rubber/plastic sheaths, composite sheaths offer well-balanced overall performance.

In addition to the common sheath types above, there are special-purpose sheaths designed to meet specific requirements. For example, radiation-resistant sheaths are used for cables operating in radiation environments, while biological-resistant sheaths protect against damage from termites, rodents, and other organisms. These special sheaths employ specific materials and manufacturing processes tailored to particular application conditions.

Selecting the correct power cable is essential for the safe operation of a diesel generator set and stable power transmission. Multiple factors must be considered, including cable cross-sectional area, length, operating environment, load characteristics, and safety margin.

The cable cross-sectional area primarily depends on the generator’s rated current and voltage. Generally, higher generator power requires a larger cable cross section to safely carry higher current.

According to an empirical formula, a diesel generator requires approximately 1.8 A of current per kilowatt of power. For example, a 100 kW diesel generator draws about 180 A (100 kW × 1.8 A/kW).

When selecting cable size based on current-carrying capacity:

- Cables below 10 mm² are typically calculated at 5 A/mm²

- Cables above 100 mm² at about 2 A/mm²

- Cables of 25–35 mm² at 3–4 A/mm²

- Cables of 70–95 mm² at about 2.5 A/mm²

Based on these values, a 100 kW generator typically requires a 70–95 mm² cable. These figures are theoretical; in practice, adjustments must be made according to cable length and operating conditions.

Cable length significantly affects voltage drop. Longer cables have higher resistance, which can cause excessive voltage drop and impair generator performance. Since resistance is proportional to length and inversely proportional to cross-sectional area, longer cable runs require larger cable sizes to keep voltage drop within acceptable limits.

The operating environment plays a critical role in cable selection. Different environments impose different performance requirements:

- High-temperature environments require heat-resistant cables

- Humid environments require good moisture resistance

- Corrosive environments require corrosion-resistant materials

If cables are exposed to vibration or mechanical stress, adequate mechanical strength is also necessary. Based on these conditions, appropriate cable types, such as rubber-sheathed or PVC cables, should be selected.

Load characteristics also affect cable selection. Different loads have different current demands:

- Inductive loads (such as motors) produce high starting currents and require cables that can withstand current surges

- Capacitive loads require attention to cable capacitance effects

The power factor of the load is another important consideration. Low power factor loads can cause generator overload, so power factor correction should be considered during system design.

A safety margin ensures reliable cable operation under varying conditions. Typically, a safety factor of 1.25–1.5 is applied, depending on operating environment, load characteristics, and duty conditions, to prevent overheating and failures.

In practical applications, the installation and use of diesel generator power cables require attention to the following points:

Cable installation should be carried out by qualified electricians with sufficient experience. Key points include:

Grounding and Ground-Fault Protection: All wiring must comply with relevant electrical standards, including grounding and ground-fault protection requirements, to ensure operational safety.

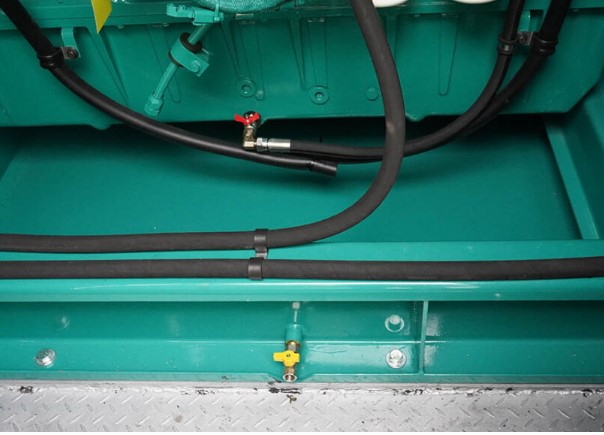

Use of Flexible Cables: Since generators produce vibration during operation, flexible cables should be used to connect the generator to prevent damage to terminals or circuit breakers. If flexible cables cannot be used directly, a junction box should be installed near the generator, with a short flexible connection.

Cable Routing: Cables should be installed in conduits or cable trays and must never be fixed directly to the generator set. Bending should comply with the minimum bending radius to avoid insulation damage.

Cable Matching: Cables must match the generator’s output voltage and current. Installation method, ambient temperature, and proximity to other cables must be considered. For single-core copper cables, non-magnetic metal sheaths (such as aluminum or copper) or non-metallic materials should be used. If magnetic metal sheaths are used, longitudinal slots must be cut to prevent eddy currents.

Load balance is critical in three-phase systems. Uneven load distribution can cause overheating of alternator windings and damage sensitive three-phase equipment. Loads should be evenly distributed across phases, and existing systems should be rebalanced when connecting a generator.

Power factor is a key indicator of load behavior. If the power factor drops below 0.8 lagging (inductive), the generator may be overloaded. Ideally, power factor should remain between 0.8 and 1.0.

When installing automatic or manual power factor correction equipment (such as capacitors), leading power factor must be avoided, as it can cause voltage instability and dangerous overvoltage. During generator operation, all power factor correction devices should be disconnected.

Choose Reputable Manufacturers: Cable quality directly affects generator safety and power reliability. Always purchase cables from reputable manufacturers that comply with recognized standards. Standard-compliant cables typically have neat packaging, proper insulation thickness, high-quality conductors, and clear certification markings.

Check Cable Markings: Standard cables feature clear markings such as trademarks, manufacturer names, applicable standards, and certification marks (e.g., CCC). Markings usually repeat at intervals of no more than 500 mm, allowing easy identification during use.

Inspect the Conductor: The conductor is critical to current-carrying capacity and safety. High-quality copper conductors are bright, uniform, and glossy. Standards generally require oxygen-free copper. Inferior materials, such as recycled or “black rod” copper, pose safety risks. Conductor diameter should also meet standard requirements.

Verify Cable Length: Although length marking is not always mandatory, standard-compliant cables usually include meter markings. While meter markings alone do not guarantee compliance, their presence, combined with proper markings and conductor quality, helps confirm cable authenticity.

Cable Cross-Section Selection: Using the empirical formula, a 200 kW generator draws approximately 360 A (200 kW × 1.8 A/kW). A cable configuration of 3 × 120 mm² + 1 × 60 mm² is suitable, providing sufficient current capacity without unnecessary oversizing. If aluminum conductors are used, the cross-sectional area should be increased by 2–3 times.

Cable Length Consideration: Long cable runs increase voltage drop. For extended distances, cable resistance must be calculated and cross-sectional area increased accordingly to maintain acceptable voltage levels.

Operating Environment: If the generator operates in humid or corrosive environments, waterproof and corrosion-resistant cables should be selected. Where vibration or mechanical stress exists, cables with adequate mechanical strength are required.

Load Balance and Power Factor Control: Load balance must be ensured to prevent overheating and equipment damage. Power factor should be calculated and corrected if necessary, ensuring it remains within the optimal range of 0.8–1.0. During generator operation, all power factor correction devices should be switched off to prevent leading power factor conditions.

Selecting and matching power cables for diesel generator sets is a complex process that requires careful consideration of cable cross-sectional area, length, operating environment, load characteristics, and safety margins. Proper cable selection ensures safe generator operation and reliable power transmission. In practical applications, attention must also be paid to proper installation, load balancing, and power factor control to ensure stable and safe system performance. Ultimately, choosing the right power cable is essential to maximizing generator reliability, safety, and overall performance. By following the guidance in this article, users can make informed decisions when selecting diesel generator power cables, ensuring safe operation and stable power delivery under real-world conditions.