At a critical juncture in today's global energy transition, the search for efficient and environmentally friendly energy solutions has become a worldwide focus. Natural gas–fired generator sets, as a clean and efficient form of energy utilization, are gradually gaining prominence. Among them, gas turbine generator sets, with their distinctive advantages, occupy an increasingly important position in the energy sector.

Gas turbine generator sets hold a significant place in the energy field due to their unique strengths. So what exactly are the outstanding advantages of gas turbine generator sets? Below, we explore their notable performance in terms of environmental benefits, energy utilization efficiency, installation and operational flexibility, and fuel adaptability.

As global awareness of environmental protection continues to grow, reducing pollutant emissions has become a top priority for the energy industry. Gas turbine generator sets stand out for their low-emission characteristics. Compared with traditional oil-fired and coal-fired power generation units, gas turbine generator sets produce almost no particulate matter or sulfur dioxide during operation, and their nitrogen oxide (NOₓ) emissions are far lower than those of conventional power generation methods. This makes gas turbine generator sets an ideal clean energy option for urban and industrial areas, helping to improve air quality and reduce environmental pollution.

Another significant advantage of gas turbine generator sets lies in their high energy utilization efficiency. Gas turbines directly convert the chemical energy of fuels such as natural gas into mechanical energy, which then drives generators to produce electricity. This energy conversion process is highly efficient, typically achieving efficiencies of 30%–40% or even higher. Moreover, gas turbines can be operated in combination with steam turbines and other equipment to form combined-cycle power generation systems, further boosting overall efficiency to 50%–60%. This highly efficient mode of energy utilization not only reduces energy consumption but also lessens dependence on natural resources, delivering substantial economic and environmental benefits.

Gas turbine generator sets offer great flexibility in both installation and operation. Their relatively compact size and lighter weight allow for flexible arrangement according to different application scenarios. Whether in large-scale power plants or small distributed power stations, gas turbine generator sets can adapt well. During operation, they are capable of rapid start-up and shutdown and demonstrate strong adaptability to grid conditions. When grid loads fluctuate significantly, gas turbine generator sets can quickly adjust output power to maintain stable grid operation. This flexibility makes them ideal for peak-shaving and standby power applications, effectively enhancing grid reliability and stability.

Gas turbine generator sets exhibit strong adaptability to different fuels. In addition to conventional fuels such as natural gas, they can also utilize unconventional fuels including biogas, coal mine gas, and coke oven gas. This provides significant advantages in resource utilization, enabling the effective use of various waste or hazardous gases and turning waste into valuable energy. For example, methane and biogas generated in coal mines and landfill sites, if left unused, not only waste resources but also cause environmental pollution. Gas turbine generator sets can convert these gases into electricity, achieving efficient resource utilization while reducing greenhouse gas emissions.

Next, we take a closer look at the technical requirements of gas turbine generator sets in terms of fuel quality, operating parameters, and maintenance. These requirements are not only essential for normal operation but are also key to achieving optimal performance.

Natural gas is one of the most commonly used fuels for gas turbine generator sets, and its quality has a significant impact on unit performance and service life. Within 1 meter upstream of the gas inlet pressure-regulating valve, the gas pressure should be controlled at 100–300 kPa (for boosted units) or 50–300 kPa (for non-boosted units). The volumetric methane content should be no less than 70%, H₂S content should not exceed 20 mg/Nm³, impurity particle size should be less than 5 μm, and impurity concentration should not exceed 30 mg/Nm³. If the natural gas contains high concentrations of sulfur, ammonia, or similar components, severe corrosion may occur to spark plug electrodes, lubricating oil, and internal components, increasing wear and reducing service life.

As a renewable energy source, biogas has broad utilization prospects. For gas turbine generator sets, biogas temperature should not exceed 40°C, pressure should be maintained between 3–10 kPa, and the pressure fluctuation rate should not exceed 1 kPa/min. The volumetric methane content should be no less than 40%, with a variation rate not exceeding 2%/min. H₂S content should not exceed 200 mg/Nm³, NH₃ content should not exceed 20 mg/Nm³, impurity particle size should be no greater than 5 μm, impurity concentration should not exceed 30 mg/Nm³, and moisture content should not exceed 40 g/Nm³. For biogas with methane content between 30% and 40%, special configurations and appropriately selected unit models are required.

Coal mine gas mainly originates from coal mining operations. Its temperature should not exceed 40°C, pressure should be maintained between 3–10 kPa, and pressure fluctuation rate should not exceed 1 kPa/min. The volumetric methane content should be no less than 9%, with a variation rate not exceeding 2%/min. For coal mine gas with methane content below 30%, the combined volumetric content of methane and oxygen should be no less than 28%, and oxygen content should be no less than 16%. Impurity particle size should not exceed 5 μm, impurity concentration should not exceed 30 mg/Nm³, and H₂S content should not exceed 200 mg/m³. If the gas composition falls outside specified limits, consultation with the manufacturer is required to verify feasibility.

Coke oven gas is a by-product generated during the coking process and has certain utilization value. Within 1 meter upstream of the gas inlet pressure-regulating valve, gas temperature should not exceed 40°C, pressure should be 3–10 kPa, and pressure fluctuation rate should not exceed 1 kPa/min. Hydrogen volumetric content should not exceed 60%, H₂S content should not exceed 200 mg/Nm³, NH₃ content should not exceed 20 mg/Nm³, tar content should not exceed 50 mg/Nm³, impurity particle size should not exceed 5 μm, impurity concentration should not exceed 30 mg/Nm³, and moisture content should not exceed 40 g/Nm³. Similarly, high concentrations of sulfur or ammonia can adversely affect unit performance and service life.

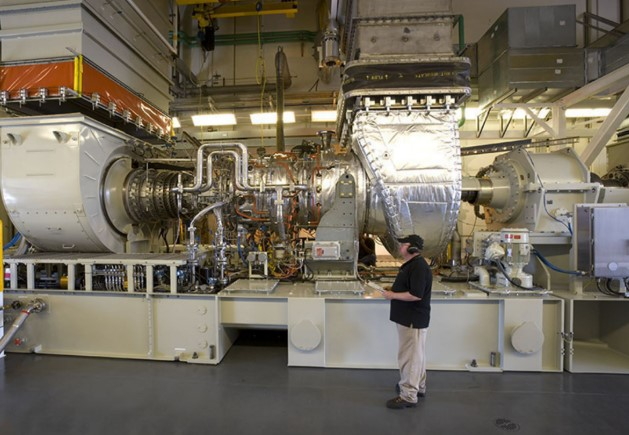

The efficient operation of gas turbines depends on sophisticated structural design and high-precision manufacturing processes. A gas turbine primarily consists of three core components: the compressor, combustion chamber, and turbine. These components work together to convert the chemical energy of fuel into electrical energy. Each operates under extreme conditions, imposing stringent requirements on materials and manufacturing processes. The compressor draws in and compresses air, the combustion chamber mixes and burns fuel with air, and the turbine uses the resulting high-temperature, high-pressure gas to rotate blades that drive the generator.

Gas turbines are mainly composed of the compressor, combustion chamber, and turbine. Both compressors and turbines are equipped with blades that play a crucial role during operation. Combustion chamber nozzles and turbine blades are the most critical and difficult-to-manufacture components. According to data from Thunder Said Energy, blades account for approximately 12% of total unit cost, turbine assemblies about 36%, with the remainder attributed to instrumentation, control systems, and other components.

Turbine blades are among the most critical components of a gas turbine, operating in regions with the highest temperatures, most complex stresses, and harshest environments. They are numerous, complex in shape, demanding in dimensional accuracy, and difficult to manufacture, directly affecting turbine performance. Their primary function is to continuously convert the energy of high-temperature, high-pressure gas into mechanical energy. Depending on operating conditions, turbine blades are classified into high-pressure and low-pressure blades. High-pressure turbine blades operate at temperatures of 1400°C–2200°C and pressures of 20–50 atm, rotating at speeds of up to 15,000 rpm. The centrifugal force acting on the blade root can reach up to 10,000 times the blade's weight, equivalent to 10–15 tons. Therefore, high-pressure turbine blades must possess exceptional high-temperature resistance, creep resistance, fatigue resistance, corrosion resistance, and long service life. After passing through the high-pressure turbine, gas energy decreases, resulting in relatively milder conditions for low-pressure turbine blades and correspondingly lower performance requirements.

Gas turbine castings are divided into casings and critical cast components. Key cast components include six main parts, such as stator vane carriers, compressor bearing housings, turbine bearing housings, and radial bearing housings. Compressors, combustion chambers, and turbines all require casings, which are typically large-diameter, thin-walled, semi-cylindrical structures. Manufacturing accuracy and quality of these components are decisive factors in overall turbine performance.

Gas turbines involve high technical barriers, mainly in design, materials, and manufacturing processes. Internal gas flow and combustion processes are complex. Advanced aerodynamic design can significantly improve compressor and turbine efficiency, relying on high-precision computational fluid dynamics (CFD) simulations to optimize blade profiles and flow passages, ensuring stable, uniform airflow and minimizing energy losses. Compressor design focuses on aerodynamic optimization to enhance efficiency by reducing flow losses and secondary flow effects. Key technologies include high-load, high-efficiency, high-speed aerodynamic design, stable aerodynamic performance design, full-machine aerodynamic simulation and testing, and rotor strength and vibration design.

Combustion chamber design is also challenging. It must ensure complete combustion for high thermal efficiency while suppressing pollutant formation. Premixed combustion technology is commonly adopted, allowing fuel and air to mix thoroughly before entering the combustion zone, promoting uniform combustion, reducing localized hot spots, and minimizing harmful emissions.

Due to high operating temperatures, material selection for combustion chambers and turbine blades is critical. Advanced combustion chamber designs typically use high-temperature alloys or ceramic matrix composites, combined with cooling techniques such as film cooling, impingement cooling, and convective cooling to reduce wall temperatures and extend service life. Turbine blades generally use nickel-based or cobalt-based superalloys. Stator blades, subjected to higher thermal loads and temperature non-uniformity, often use cobalt-based superalloys for superior thermal fatigue, oxidation, and corrosion resistance. Rotor blades, while experiencing slightly lower thermal loads, must withstand high centrifugal stress, vibration, and high-speed gas erosion, requiring excellent high-temperature strength and creep resistance, typically achieved with nickel-based superalloys. To further enhance thermal, oxidation, and corrosion resistance, the first two turbine stages are usually coated with 50–600 μm thermal barrier coatings (TBCs), consisting of a metallic bond coat and a ceramic topcoat.

Gas turbines demand extremely high manufacturing precision. Turbine blade production requires precision casting and machining with minimal dimensional tolerances, as even slight deviations can affect performance. Turbine blades are considered first-tier critical components, serving as key indicators of overall turbine advancement. Their manufacturing process involves complex routes with more than ten steps in both casting and precision machining, including sealing and de-sealing, blade root machining, film cooling hole processing, aluminide coating, component welding, thermal barrier coating, and flow testing. These advanced processes contribute to the high added value of hot-end turbine blades.

Gas turbine assembly is a late-stage process in manufacturing and repair, characterized by low automation, high precision requirements, and heavy workloads. Compared with aircraft or automotive industries, gas turbine assembly is less digitized and automated. The complex structure and large number of components result in intricate assembly procedures, largely performed manually, requiring highly skilled personnel. Assembly quality directly affects engine performance, lifespan, and reliability. High precision is required to ensure concentricity, axial clearances, and other parameters. Key technologies include rotor assembly concentricity control, rotor–stator clearance and coaxiality measurement, precision flow and sealing tests, and turbine guide vane throat area measurement. Assembly workload accounts for approximately 50% of total engine repair work.

- Large Power Plants: Due to their high power output, gas turbine generator sets are primarily used in large and medium-sized power plants. They serve as main power generation equipment, providing stable electricity for cities and industrial zones. Their high efficiency and low emissions make them ideal for modern large-scale power plants. Combined-cycle operation further enhances efficiency and reduces generation costs.

- Distributed Power Stations: Gas turbine generator sets are also widely used in small distributed power stations located throughout urban and industrial areas. Their flexible installation and operation suit distributed applications well. In such systems, gas turbines can provide both electricity and heat through combined heat and power (CHP) systems, improving efficiency and reducing energy consumption.

- Standby Power Supply: In facilities requiring high power reliability, such as oil and gas fields, airports, hotels, and hospitals, gas turbine generator sets play a vital role as standby power sources. They can start within seconds during outages, providing reliable power to ensure uninterrupted operation. As long as gas supply continues, power generation persists, and it stops simply by switching off, without additional user intervention. This reliability makes them indispensable in critical facilities.

As a clean and efficient energy utilization technology, gas turbine generator sets are of great significance during today's energy transition. Their notable environmental benefits, high efficiency, flexible installation and operation, and wide fuel adaptability allow them to stand out in the energy sector. Although they have high technical requirements, ongoing technological advancements and innovation continue to improve their performance and reliability. In conclusion, gas turbine generator sets represent a clean energy technology with tremendous potential, worthy of in-depth research and widespread application. Let us look forward to their outstanding performance in the future energy landscape, bringing greater benefits to our lives and environment.