Causes and Solutions for Low Diesel Generator Compression Ratio

On this page

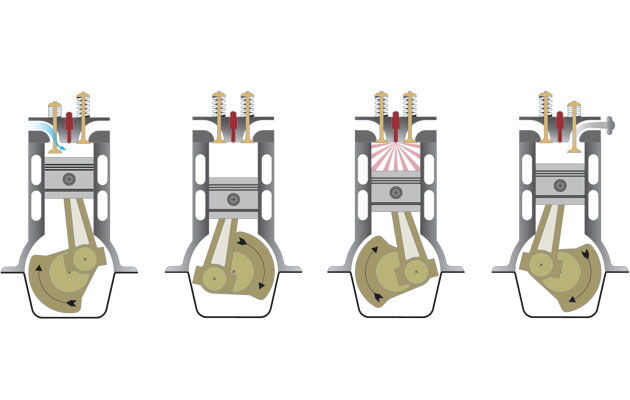

In diesel generators, the compression ratio is a crucial parameter influencing engine performance and fuel efficiency. It is the ratio of the cylinder's volume before and after compression, determining the pressure within the cylinder and affecting power output and fuel consumption. Over time, various factors can cause the compression ratio to decrease, leading to reduced engine power and increased fuel consumption. This article explores common causes of compression ratio reduction in diesel generators and offers solutions for maintaining optimal performance.

The piston being positioned too low at the compression top dead center is a significant cause of decreased compression ratio in diesel generator sets. When the piston’s top dead center position within the cylinder is lower than the design standard, the compressed cylinder volume increases, resulting in a reduced compression ratio. This condition is usually caused by the following factors.

During the operation of a diesel engine, the clearance between parts is crucial for the stability of the compression ratio. If the clearance between the crankshaft main bearing and the main shaft neck, the connecting rod bearing and the connecting rod shaft neck, the connecting rod bushing and the piston pin, or the piston pin and the pin seat hole is too large, the actual position of the piston at the top of the compression will move down, resulting in a decrease in the compression ratio. This situation is often caused by part wear or improper assembly. Therefore, in the maintenance process, it is essential to strictly control these clearances to keep them within the allowed range to ensure that the compression ratio of the diesel engine is not affected.

Part deformation or dimensional deviation is also one of the important reasons for the decrease in the compression ratio. For example, when grinding the crankshaft connecting rod journal, if the eccentric distance is not properly adjusted, it may cause the crankshaft's rotating radius to become smaller after grinding; if the connecting rod is bent, it will shorten the center distance between the large and small end holes of the connecting rod; the pin hole of the piston pin seat hole is also skewed, which will shorten the distance from the center line of the piston pin seat hole to the top surface of the piston. These factors will cause the position of the piston at the top of the compression to move down, thereby reducing the compression ratio. Therefore, in the maintenance process, it is necessary to strictly follow the operation specifications to ensure the quality of maintenance. In addition, when replacing parts, it is necessary to check the key dimensions, such as the crankshaft rotating radius, the center distance between the large and small end holes of the connecting rod, the distance from the center line of the piston pin seat hole to the top surface of the piston, and the distance between the upper surface of the cylinder block and the center line of the main bearing seat hole, to avoid affecting the compression ratio due to the installation of unqualified or incorrect parts.

The volume of the combustion chamber directly determines the size of the compression ratio, and any factor that causes the combustion chamber volume to increase will cause the compression ratio to decrease. Here are some common situations:

When valves and valve seats are severely worn, the sinking amount of the valve may be too large, even exceeding the limit value. This will cause an increase in the combustion chamber volume, and the compression ratio will decrease accordingly. To solve this problem, it is necessary to replace the valves and seat rings in time to ensure they meet the specified standards.

If the thickness of the cylinder gasket exceeds the design requirements, or if the thickness of the gasket is increased due to human factors, the total volume of the combustion chamber will increase, resulting in a decrease in the compression ratio. The solution is to replace the cylinder gasket that meets the requirements and restore the normal compression ratio.

The concave on the top of the piston is part of the combustion chamber. If the concave is damaged due to erosion or the volume is too large due to incorrect replacement of parts, the compression ratio will also decrease. In this case, it can be checked by the water injection comparison method, and replace the qualified piston if necessary.

The swirl chamber on the cylinder head is an important part of the combustion chamber. If the swirl chamber is damaged or the manufacturing quality is unqualified, resulting in an excessive volume, the compression ratio will also decrease. At this time, a qualified cylinder head should be replaced to restore the normal compression ratio.

It should be noted that the decrease in the compression ratio is usually not caused by a single factor, but is the result of the combined effects of multiple factors. When the power of the generator set decreases, fuel consumption increases, and it is difficult to find the cause of the fault, the inspection of the compression ratio is often overlooked. To ensure that the diesel generator set always operates within the best compression ratio range, users should pay attention to the following points in daily maintenance:

Improve the quality of maintenance: Regular maintenance is the key to ensuring the stability of the compression ratio, especially after parts wear or replacement, to ensure the accuracy of the clearance and part size.

Precise measurement and selection: When repairing and replacing parts, use precision instruments for measurement, and prioritize the selection of parts that meet technical requirements to minimize assembly clearance.

Follow operational specifications: In the maintenance and maintenance process, strictly follow the operational specifications to avoid a decrease in the compression ratio due to human error.

The compression ratio of the diesel generator set is crucial for the engine's performance, and any factor that causes the compression ratio to decrease may trigger a series of performance issues. Therefore, users must pay great attention to the inspection and maintenance of the compression ratio in daily maintenance. By improving the quality of maintenance, precise measurement and selection of parts, and strictly following operational specifications, the compression ratio can be kept within the range required by the design. Only in this way can the diesel generator set operate efficiently and reliably, extend the service life of the equipment, and reduce operating costs. Through scientific management and meticulous maintenance, users can maximize the potential of the diesel generator set and provide a strong guarantee for continuous and stable power supply.