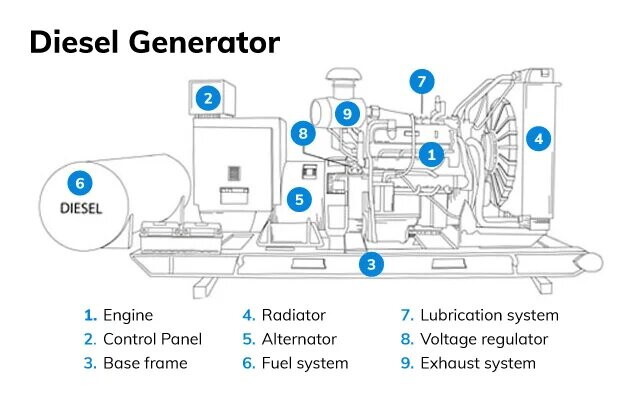

A Quick Overview of Essential Systems in Diesel Generator Sets

Diesel generators are indispensable equipment in modern society, with their reliability and stability directly impacting the continuity and reliability of power supply. To ensure the normal operation of diesel generator sets, each key system plays an irreplaceable role. In the following parts, we will have further discussion on the critical systems of diesel generators.

1. Lubrication System

The lubrication system of diesel generator sets not only provides lubrication for the machine but, more importantly, ensures that the friction surfaces between engine parts can operate normally by providing clean, adequately pressurized lubricating oil, thereby reducing wear and extending service life. Additionally, lubricating oil also functions in cooling, sealing, and preventing rust, contributing to maintaining the stability and reliability of the engine.

2. Fuel Supply System

The fuel supply system is one of the key factors in ensuring the normal operation of diesel generator sets. By precisely controlling the low-pressure oil circuit and high-pressure oil circuit, it ensures the injection of the right amount of high-pressure fuel into the combustion chamber before piston compression, maximizing combustion efficiency. The stability and precision of this system are directly related to the power output and fuel economy of diesel generator sets.

3. Intake and Exhaust Systems

The design of the intake and exhaust systems directly affects the performance and emissions of the engine. The intake system provides clean gas through components like air filters, ensuring that the engine receives sufficient oxygen to promote combustion efficiency and power output. The exhaust system effectively discharges exhaust gases through components like exhaust pipes and mufflers, reducing noise while minimizing environmental pollution.

4. Starting System

The starting system of diesel generator sets typically utilizes electric start powered by batteries. The reliability of the starting system is directly related to the startup speed and availability of the generator set. Therefore, selecting suitable starting motors and batteries and maintaining them in good condition are crucial to ensuring the rapid startup of generator sets.

5. Control and Protection Systems

The control and protection system is the brain and shield of diesel generator sets. It can monitor the operational status of generator sets, promptly detect and handle abnormal conditions, protecting them from damage. The control and protection system can also enable remote monitoring and control according to user requirements, enhancing the intelligence level of the power generation system.

6. Cooling System

The cooling system of diesel generator sets controls the engine's temperature by circulating coolant, keeping it within the normal operating range. A well-designed cooling system can effectively reduce the engine's temperature and ensure that it does not overheat and get damaged during long-term operation. Different types of cooling systems have their own advantages and disadvantages, and their selection and configuration should be based on specific circumstances.

In conclusion, the close coordination of various systems ensures the efficient and stable operation of diesel generator sets. For users, understanding the functions and components of these systems helps in promptly identifying and resolving issues, ensuring the long-term stable operation of generator sets.