Factors Ensuring Diesel Generator Rotational Velocity Stability

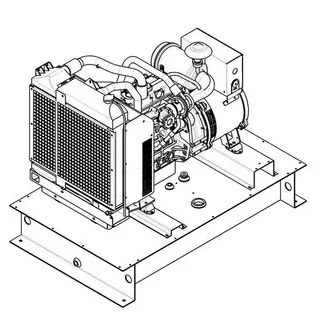

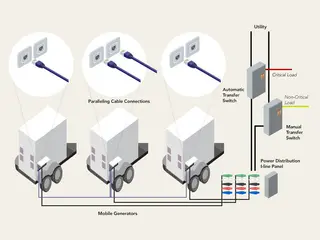

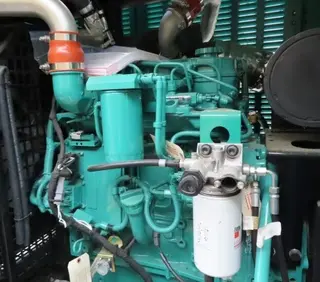

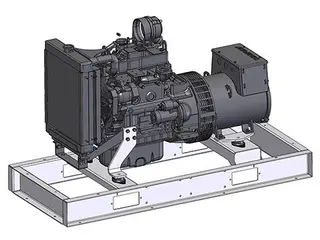

Diesel generators serve as critical power sources, playing an indispensable role in industrial production. However, prolonged operation of diesel generators can lead to issues such as unstable rotational velocities, directly impacting performance stability and potentially compromising production efficiency and equipment safety. Analysis of Key Conditions Supporting Rotational Velocity Stability The stability of a diesel generator's rotational velocity depends on several...