Avoiding Low Load Operation for High-Power Diesel Generators

On this page

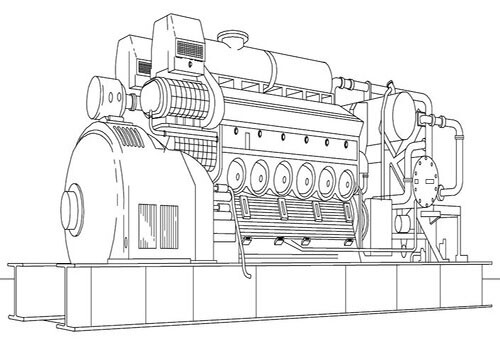

Diesel generators are commonly used as power generation equipment, and the size of the load during operation has a significant impact on their performance and lifespan. Particularly in the operation of high-power diesel generators, running at low loads is highly undesirable. This article will delve into why high-power diesel generators should not operate at low loads and the associated reasons.

In high-power diesel generators, running at low loads presents the following main problems:

1. Low combustion efficiency

The combustion process of diesel generators requires specific temperature and pressure conditions to ensure complete fuel combustion. During low load operation, the generator fails to reach the ideal combustion conditions, resulting in incomplete fuel combustion and the production of adverse combustion by-products such as carbon black and soot, thereby affecting the generator's performance and reliability.

2. Low lubricating oil temperature

The lubrication system of the generator needs to operate within an appropriate temperature range to ensure that the lubricating oil can flow properly and perform its lubricating function. During low load operation, the lack of sufficient heat due to the low load leads to a decrease in lubricating oil temperature, compromising lubrication effectiveness and increasing the risk of generator wear and failure.

3. High fuel consumption rate

Low load operation increases the fuel consumption rate of the generator. To maintain a certain speed and operational stability, the generator needs to consume more fuel under low load conditions, resulting in increased operating costs and unnecessary carbon emissions.

4. Shortened generator lifespan

Prolonged low load operation may shorten the lifespan of diesel generators. During low load operation, various components and systems of the generator fail to receive sufficient use and bedding-in, which may lead to issues such as corrosion, carbon buildup, and wear, consequently reducing the generator's lifespan and reliability.

The combustion process of diesel generators requires specific temperature and pressure conditions to ensure complete fuel combustion. During low load operation, the generator fails to reach the ideal combustion conditions, resulting in incomplete fuel combustion and the production of adverse combustion by-products such as carbon black and soot, thereby affecting the generator's performance and reliability.

2. Low lubricating oil temperature

The lubrication system of the generator needs to operate within an appropriate temperature range to ensure that the lubricating oil can flow properly and perform its lubricating function. During low load operation, the lack of sufficient heat due to the low load leads to a decrease in lubricating oil temperature, compromising lubrication effectiveness and increasing the risk of generator wear and failure.

3. High fuel consumption rate

Low load operation increases the fuel consumption rate of the generator. To maintain a certain speed and operational stability, the generator needs to consume more fuel under low load conditions, resulting in increased operating costs and unnecessary carbon emissions.

4. Shortened generator lifespan

Prolonged low load operation may shorten the lifespan of diesel generators. During low load operation, various components and systems of the generator fail to receive sufficient use and bedding-in, which may lead to issues such as corrosion, carbon buildup, and wear, consequently reducing the generator's lifespan and reliability.

To improve the operational efficiency and reliability of diesel generators, the following measures should be taken:

- Selection of an appropriate capacity generator: Choose a generator with suitable capacity according to the actual load requirements to avoid low load operation.

- Maintain operation within the rated load range: Ensure that the generator operates within the rated load range to achieve optimal performance and economic benefits.

- Regular maintenance: Carry out regular maintenance such as lubricating oil replacement, cleaning of fuel systems, and inspection and adjustment of generator parameters to extend lifespan, improve operational efficiency, and enhance reliability.

In conclusion, high-power diesel generators should avoid low load operation to prevent significant performance degradation, reduced energy efficiency, environmental pollution, and increased maintenance costs. To ensure their performance and reliability, appropriate capacity generators should be selected, and operation within the rated load range should be maintained, coupled with regular maintenance to enhance operational efficiency and reliability.