Impacts of Poor Diesel Quality on Generator Performance

On this page

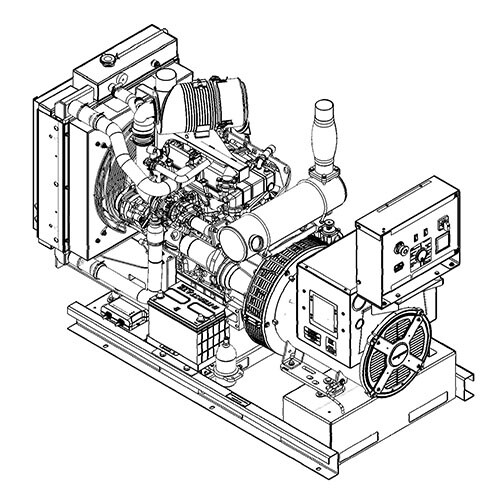

Diesel generators, as crucial energy conversion devices, play pivotal roles in various fields such as industrial production, construction sites, rural power supply, and emergency backup power. Diesel, as their primary fuel, directly impacts the performance, reliability, and environmental emissions of these diesel generators. Therefore, attention to and management of diesel quality are essential.

When considering the effects of poor diesel quality on diesel generators, several key factors come into play.

1. Decreased Combustion Efficiency

Increased impurities, moisture, or incomplete combustion by-products in diesel reduce its calorific value and combustion efficiency, leading to incomplete combustion in the generator. This not only reduces power output but can also cause carbon buildup in the combustion chamber, affecting the engine's normal operation.

2. Reduced Engine Performance

Poor diesel quality may result in carbon buildup, wear, and corrosion issues within the engine components. High-sulfur diesel can corrode the emission system and increase particulate emissions. Additionally, high impurity diesel may lead to injector clogging, uneven fuel injection, thereby affecting engine performance and stability.

3. Increased Emission Pollution

Poor diesel quality increases pollutants emitted by generators, negatively impacting the environment and air quality. Sulfur dioxide emissions from high-sulfur diesel exacerbate atmospheric pollution, while particulate matter and harmful gases from high-impurity diesel can harm surrounding environments and human health.

4. Increased Maintenance Costs

Poor diesel quality can increase the failure rate of generators, requiring more frequent maintenance and upkeep. For example, impurities can lead to clogging of fuel and air filters, accelerate component wear, and increase the cost of repairing and replacing parts.

Increased impurities, moisture, or incomplete combustion by-products in diesel reduce its calorific value and combustion efficiency, leading to incomplete combustion in the generator. This not only reduces power output but can also cause carbon buildup in the combustion chamber, affecting the engine's normal operation.

2. Reduced Engine Performance

Poor diesel quality may result in carbon buildup, wear, and corrosion issues within the engine components. High-sulfur diesel can corrode the emission system and increase particulate emissions. Additionally, high impurity diesel may lead to injector clogging, uneven fuel injection, thereby affecting engine performance and stability.

3. Increased Emission Pollution

Poor diesel quality increases pollutants emitted by generators, negatively impacting the environment and air quality. Sulfur dioxide emissions from high-sulfur diesel exacerbate atmospheric pollution, while particulate matter and harmful gases from high-impurity diesel can harm surrounding environments and human health.

4. Increased Maintenance Costs

Poor diesel quality can increase the failure rate of generators, requiring more frequent maintenance and upkeep. For example, impurities can lead to clogging of fuel and air filters, accelerate component wear, and increase the cost of repairing and replacing parts.

To mitigate the adverse effects of poor diesel quality on diesel generators, here are some recommendations:

- Select High-Quality Diesel: Purchase high-quality diesel that meets quality standards from certified suppliers to ensure its purity and stability.

- Regular Maintenance: Follow the manufacturer's recommendations for regular maintenance, including filter replacement, inspection and cleaning of the fuel system, adjusting engine parameters, etc., to ensure the generator's normal operation.

- Control Diesel Storage Conditions: When storing diesel, ensure that storage containers and environments meet relevant standards to prevent contamination or moisture ingress. Regularly check the seal of storage tanks and clean deposits inside the tank.

- Use Fuel Additives: Use appropriate fuel additives as needed to improve diesel quality and performance, such as cleaners, antioxidants, carbon-reducing agents, etc., to enhance diesel cleanliness and stability, prolonging the generator's lifespan.

In conclusion, the quality of diesel directly affects the performance, lifespan, and environmental impact of diesel generators. Measures such as selecting high-quality diesel, regular maintenance, controlling storage conditions, and using fuel additives can minimize the adverse effects of poor diesel quality on diesel generators, ensuring their efficient, reliable, and environmentally friendly operation.