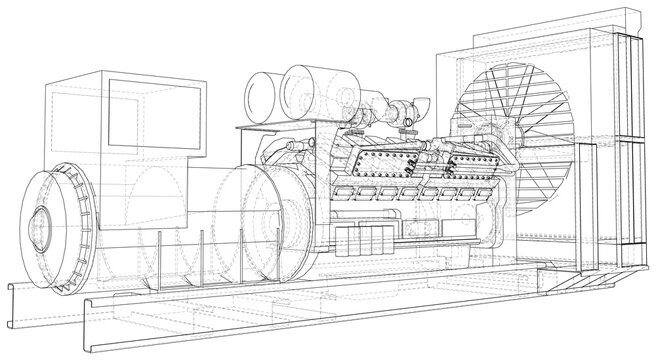

Noise Generation and Sources in Diesel Generator Sets

On this page

With the continuous growth in demand for electricity in modern society, diesel generator sets, as reliable backup power sources, have been widely utilized in various applications. However, the accompanying noise issue has become a significant challenge that cannot be overlooked. This paper aims to explore the noise generated by diesel generator sets and its sources.

Gas dynamic noise is one of the primary sources of noise in diesel generator sets. It includes low-frequency noise generated by air pressure pulsations in the intake pipe and high-frequency vortex noise produced as air flows rapidly through the intake valve. Particularly noteworthy is the significant impact of air pump noise in turbocharged internal combustion engines, with intake noise being the most prominent.

Exhaust gas noise is another important noise source in diesel generator sets. This noise mainly originates from the pressure pulsations of exhaust gas in the exhaust pipe, resulting in low to medium-frequency noise, along with high-frequency vortex noise at the flow cross-section of the exhaust valve. Turbocharged internal combustion engines exhibit more pronounced exhaust gas noise compared to non-turbocharged ones.

The cooling fan of diesel generator sets also contributes to noise generation, primarily due to the airflow produced as the fan rotates. Although this noise proportion is relatively small in the overall noise spectrum, it can be distinctly perceived in specific environments.

Combustion noise constitutes another significant noise source in diesel generator sets. It primarily arises from the variation in gas pressure within the cylinder and the high-frequency vibrations induced by shock waves, transmitted through the engine's structure to the surroundings.

As the speed increases, mechanical noise in diesel generator sets also intensifies. This encompasses piston knock noise, valve mechanism noise, as well as vibrations and impact noise generated by gear transmissions. These noises not only affect the normal operation of the equipment but also cause disturbance to the surrounding environment.

The generator itself produces noise, including electromagnetic noise and fan noise resulting from the disturbance of air by the cooling fan. These noises to some extent impact the overall noise level of the generator set.

Structural support noise arises from vibrations transmitted from the machinery to the supporting structure or generated within the supporting and coupling structures themselves. Its magnitude depends on factors such as the balance of the internal combustion engine generator, anti-vibration materials, quality, and the natural frequency of the structure itself.

To address these noise sources, a series of management measures can be implemented to reduce the noise level, including optimizing equipment design, regular inspection and maintenance, proper arrangement of equipment, and the use of soundproof enclosures or panels for noise control. By considering various factors comprehensively and adopting corresponding management measures, the noise level generated by diesel generator sets can be effectively reduced to meet environmental and personnel requirements.