Decoding Four Stroke Diesel Engine Operation in Generators

Diesel generator has long been integral to various industries due to their high efficiency and fuel economy. Among them, four-stroke diesel engines are widely utilized for their simplicity and stable power output. This article delves into the working principle of four-stroke diesel engines in diesel generators and elucidates the detailed processes of each stroke.

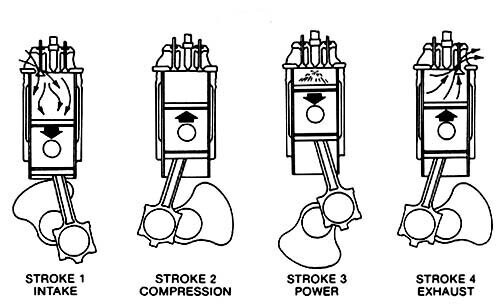

1. Intake Stroke

The intake stroke marks the initiation of the diesel engine cycle and is pivotal for oxygen intake and exhaust gas expulsion. As the piston moves from the top dead center to the bottom dead center, the intake valve opens while the exhaust valve remains closed. Fresh air from the surroundings enters the cylinder through the intake valve, driven by the low-pressure zone created by the descending piston. The quantity of air intake significantly impacts subsequent combustion, directly influencing energy release and power output.

2. Compression Stroke

During the compression stroke, as the piston moves from the bottom dead center to the top dead center, both intake and exhaust valves are closed. The piston gradually compresses the air drawn in during the intake stroke, increasing its temperature and pressure. This stage aims to elevate the compression ratio of the air to achieve higher temperatures and pressures during combustion, thereby enhancing combustion efficiency.

3. Power Stroke

The power stroke constitutes a crucial phase in the diesel engine cycle. Here, as the piston moves from the top dead center to the bottom dead center, both intake and exhaust valves remain closed. The high-pressure fuel injector sprays fuel into the combustion chamber, mixing with the high-temperature, high-pressure air. As the temperature surpasses the auto-ignition point of diesel, the fuel self-ignites, releasing substantial thermal energy. This energy propels the piston downward, driving the rotation of the crankshaft, thus generating mechanical work. The combustion process efficiently harnesses the energy of the fuel, thereby enhancing the engine's efficiency.

4. Exhaust Stroke

During the exhaust stroke, as the piston moves from the bottom dead center to the top dead center, the intake valve closes, and the exhaust valve opens. Exhaust gases are expelled from the cylinder, preparing the cylinder for the entry of fresh air. As the piston ascends, residual exhaust gases are expelled, creating a clean working environment for the next cycle.

Four-stroke diesel engines convert chemical energy into mechanical work through a precise cycle, providing stable and efficient power output. While this article outlines an idealized working process, real-world diesel engine operation is influenced by various factors, including timing control of intake and exhaust valves, and performance of fuel injection systems. A deeper understanding of diesel engine principles contributes to improving performance and reducing energy consumption.