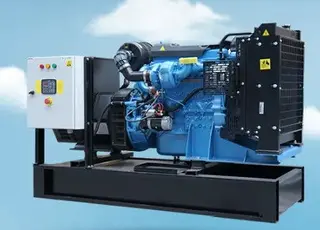

Diesel Generator Power Failure Inspection and Maintenance

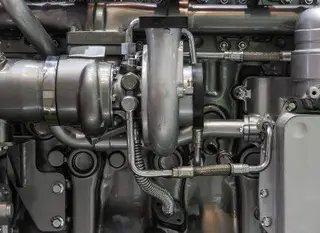

Diesel generators are crucial pieces of equipment, and like any machinery, they can experience power failures during regular operation, leading to outages. To keep everything running smoothly, it's essential to quickly identify and fix any power issues. This guide will walk you through common causes of power failures and how to inspect your diesel generator to get it back on track. Fuel Supply System Check The fuel system is at the heart of your diesel generator's operation. If something...