Analysis of Diesel Generator Exhaust Smoke

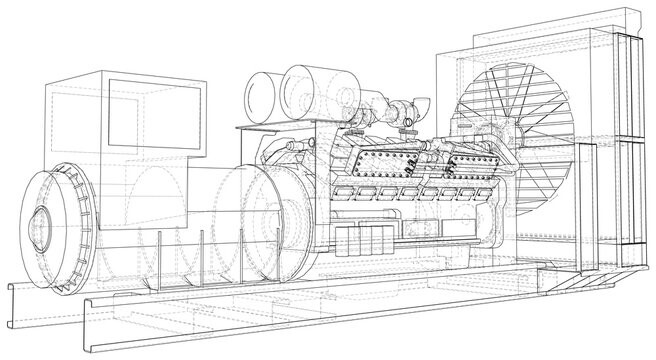

In industrial production, diesel generators serve as crucial power generation equipment, and monitoring the color of exhaust smoke emitted from their exhaust pipes has become a common method for diagnosing operational issues. Ideally, the smoke emitted after combustion should be colorless and transparent gas. However, the appearance of different-colored smoke often indicates various operational problems influenced by factors such as fuel quality, engine wear, and operating environment. Below is a detailed analysis of the faults represented by different colors of exhaust smoke from diesel generators.

Black Smoke: Causes and Solutions for High-Load Operation

Black smoke tends to occur during high-load operation of the machine. It is primarily caused by incomplete combustion of fuel, possibly due to factors such as excessive air intake, insufficient fuel supply, or injector malfunctions. Black smoke not only decreases the machine's fuel efficiency and increases exhaust emissions but also leads to the formation of carbon deposits inside the exhaust pipe and engine components. The accumulation of carbon deposits may result in severe engine malfunctions such as piston ring sticking and valve seizure, thereby compromising the reliability and stability of the generator.

White Smoke: Addressing Cold Weather Challenges

White smoke commonly arises from operating the machine in excessively cold environments or during cold weather conditions. In such cases, the low temperature inside the cylinder inhibits complete combustion of fuel, leading to the emission of unburned fuel along with water vapor, causing the white smoke phenomenon. Additionally, white smoke may also result from poor-quality fuel or clogged injectors, causing incomplete combustion. Prompt inspection and replacement of fuel, along with ensuring the machine operates at an appropriate ambient temperature, can prevent unnecessary combustion issues.

Blue Smoke: Resolving Issues with Low-Load Operation

Blue smoke typically appears during low-load operation of the machine. It may occur due to lower temperatures inside the combustion chamber, resulting in incomplete combustion, and the entry of lubricating oil into the combustion chamber. The emission of blue smoke may be accompanied by an irritating odor due to the combustion of lubricating oil producing harmful substances. Furthermore, the generation of blue smoke may also indicate mechanical structural issues in the engine, such as cylinder liner wear or piston ring damage. Therefore, upon observing blue smoke emissions, a comprehensive inspection of the engine is necessary to ensure the proper functioning of all components.

Analyzing the color of exhaust smoke from diesel generators enables timely identification and resolution of operational issues, ensuring smooth operation, extending equipment lifespan, and reducing adverse environmental impacts. Maintenance personnel should implement appropriate maintenance measures based on the characteristics of different smoke colors to enhance the stability and reliability of diesel generators, thereby ensuring the uninterrupted progress of industrial production.