Comparison of Diesel Generator Cooling Methods

Efficient cooling is crucial for the operation of diesel generator units, ensuring prolonged and stable performance. Common cooling methods for diesel generators of varying scales and types include air cooling, hydrogen cooling, and water cooling. Below, we provide a detailed comparison of these three cooling methods.

Air Cooling

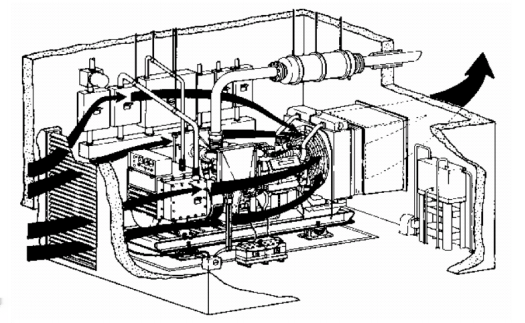

Air cooling is achieved through the use of fans to circulate air. Cold air is directed towards the winding ends, stator, and rotor of the diesel generator unit to dissipate heat. After absorbing heat, the air becomes hot and is expelled through the air ducts via a cooling radiator. The cooled air is then recirculated into the generator internals by the fan, effectively achieving heat dissipation. This method is suitable for medium and small-sized synchronous generator units.

Hydrogen Cooling

Hydrogen cooling utilizes hydrogen as the cooling medium. The heat dissipation properties of hydrogen are superior to those of air, making it the preferred choice for cooling large steam turbine generator units. This method effectively reduces the temperature of the generator unit, enhancing operational efficiency.

Water Cooling

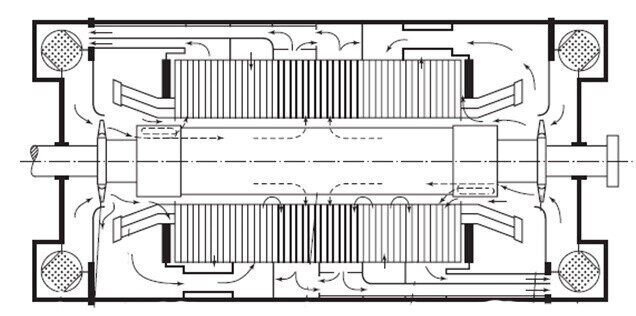

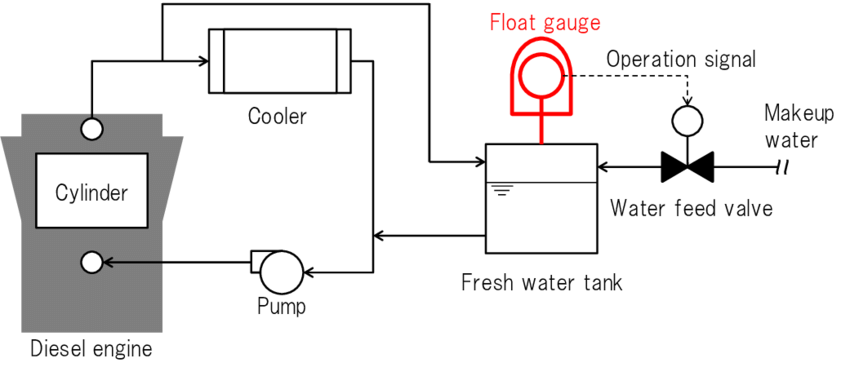

Water cooling is a more advanced cooling method, particularly suitable for large and medium-sized generator units. It involves dual water cooling systems for both the stator and rotor.

1. Stator Cooling Water System: In the stator cooling water system, cold water flows from an external water system to the inlet rings mounted on the stator cores. It then passes through insulated pipes to individual coils, absorbs heat, and is collected at the outlet rings before being discharged into an external water system for cooling.

2. Rotor Cooling Water System: The rotor cooling water system, on the other hand, enters through inlet supports, flows into the central hole of the rotor shaft, and then through longitudinal holes to a water reservoir. After absorbing heat from the coils, the water flows into the outlet reservoir and is discharged through drainage holes on the outer edge of the outlet supports.

2. Rotor Cooling Water System: The rotor cooling water system, on the other hand, enters through inlet supports, flows into the central hole of the rotor shaft, and then through longitudinal holes to a water reservoir. After absorbing heat from the coils, the water flows into the outlet reservoir and is discharged through drainage holes on the outer edge of the outlet supports.

Due to water's superior heat dissipation properties compared to air and hydrogen, water cooling is the preferred choice for newly constructed large and medium-sized generator units.

In conclusion, different generator units employ different cooling methods based on their scale and performance characteristics. The selection of the most suitable cooling method is crucial to ensure the efficient and stable operation of the generator unit.