Noise Control in Diesel Generators

With the increasing concern over environmental noise in modern society, noise control in diesel generators has become a topic of great interest. Among the various methods of noise reduction for diesel generators, the most fundamental approach lies in addressing the source of the noise, utilizing conventional techniques such as mufflers, sound insulation, absorption, and vibration isolation, all of which have proven to be the most effective.

1. Reduction of Exhaust Noise

Exhaust noise typically represents the primary source of noise in generator units, characterized by high noise levels, rapid exhaust velocities, and considerable difficulty in control. To address this issue, specially designed impedance-type composite mufflers can be employed, which generally reduce exhaust noise by 40-60 decibels. Such mufflers effectively attenuate exhaust noise, thereby enhancing the operational environment of the generator.

2. Reduction of Axial Fan Noise

When dealing with noise from diesel generator cooling fans, consideration must be given to the allowable pressure loss in the exhaust duct and the required level of noise reduction. To achieve this, resistive baffle-type silencers can be used to effectively reduce the noise from axial fans. These silencers, characterized by their simple structure, deliver significant results in noise control, thereby improving the operational quality of the generator.

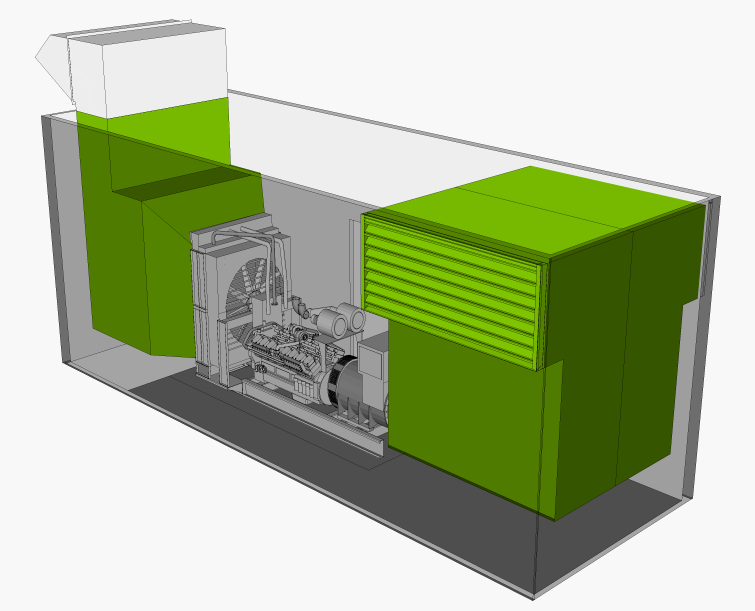

3. Enhancing Acoustic Conditions in the Generator Room

- Soundproofing in the Generator Room: Effective soundproofing in the generator room is crucial as it directly affects the propagation and range of generator noise. By employing appropriate soundproofing materials and techniques, the noise level within the generator room can be significantly reduced, thereby enhancing the working environment. In addition to using fireproof soundproof doors and windows, any holes or gaps in the generator room should be sealed to ensure soundproofing effectiveness.

- Sound Absorption: Sound absorption treatment on the walls of the generator room is one of the essential methods for reducing noise. By utilizing perforated plate resonance sound absorption structures, noise generated by the generator can be effectively absorbed, thus improving the acoustical environment within the generator room.

- Vibration Isolation for the Generator Unit: Prior to installation, strict vibration isolation treatment should be carried out according to the manufacturer's specifications to prevent the long-distance propagation of structural noise. For existing generator units exhibiting significant vibration sensitivity, vibration isolation treatment should also be implemented to reduce the propagation of vibration noise.

In conclusion, effective noise control in diesel generators necessitates the comprehensive use of techniques like mufflers, sound insulation, absorption, and vibration isolation. This ensures compliance with environmental noise regulations and creates a tranquil and conducive environment for both work and living. Proper design and scientific approaches can greatly enhance the operational efficiency and reliability of diesel generators.